Development of the Porsche 935/78 ‘Moby Dick’

New engines with water-cooled heads joined forces with a breakthrough in rules interpretation to help Porsche create a never-forgotten race car. We are, of course, talking about the 935/78‘Moby Dick’, one of the most spectacular 911 derivatives to date…

Words Karl Ludvigsen

Photography Porsche Corporate Archives

WHALE OF A TIME

Development of the 935/78 ‘Moby Dick’.

In the 1970s, during the regime of Porsche CEO, Ernst Fuhrmann, Zuffenhausen was embracing water cooling. The 928 and 924 were watercooled from the start and, at the racetrack, factory motorsport engineer, Hans Mezger, had been trying to water-cool four-valve heads, chiefly because tests had shown poor results with air-cooled four-valve designs. “If four valves will give better results, we will have them. We have to pull out all the stops,” Fuhrmann told his engineers. The resultant engine, said Mezger, “was the basis of everything we did for the next two decades.”

Although pulling out all the stops would have meant liquid cooling for both heads and cylinders, the latter had to remain air-cooled under Group 5 racing rules. Also, the original 911 Turbo’s Type 930 crankcase had to be carried over, albeit with permitted modifications — forging for the stock 3.3-litre crankshaft could be adopted for the 3.2-litre version (designated Type 935/79) using the Tenifer nitriding process to enhance hardness of the journals.

IN ITALY, THE MINUTES BEFORE RACE END, A STONE SEVERED THE BELT DRIVING THE

Strikingly, Porsche tradition was maintained in the design of the cylinder heads for the new engine. This is to say each cylinder had its own head taking the form of an individual aluminium casting with inserted valve seats. The casting included much of the inlet and exhaust tracts, both of which were bifurcated within the port, meaning the inlets and outlets from the paired valves were circular. At the bottom (or exhaust side) of each head was an inlet for cooling water from a manifold. This was fed by a water pump driven by the back end of the exhaust camshaft, one for each side of the engine. Another manifold at the top drew off warm water from each head at a point near the inlet ports. Each side had a separate coolant circuit with its own fender-mounted radiator.

Concern regarding head gasket durability — a problem with the 935/77 — was definitively dealt with by welding each head to its air-cooled cylinder. This was done by means of electron-beam welding, an exacting process. “It was not easy,” recalled Mezger, “but we made it work.” The heat of the process inevitably distorted some of the cylinders. Indeed, on average, only one of every two produced passed muster.

The finned Silumin cylinders were cooled by a 210mm axial fan mounted vertically at the front of the engine (the end opposite the clutch). Although delivering only thirty percent of the airflow produced by the 226mm fan of a fully air-cooled Porsche engine — but absorbing only four horsepower — the new fan reduced the temperature of the cylinders from 280°C to 200°C at equal levels of engine power.

DURING PRACTICE FOR LE MANS, ROLF STOMMELEN WAS TIMED AT 227.5MPH ON THE MULSANNE STRAIGHT

Welding the cylinders to the heads was feasible because the engine made use of four valves per cylinder placed at the narrower included angle of 30°, made up by 14° from the vertical for the inlet valves and 16° for the exhausts. This was the value for the 3.2-litre flat-six. A smaller 2.1-litre version was also made. At 14.5° and 16.5°, its valve angles were fractionally wider and could still be withdrawn and inserted through their permanently attached cylinder. The new head used cup-type tappets, which were placed above the coil valve springs, as opposed to surrounding them. Each tappet’s small diameter kept them light, at some cost in a greater width of the engine. The smaller engine had the larger tappet diameter: 33mm against 31mm in the bigger unit.

Dual coil springs surrounded the inserted valve guides. The 8mm valve stems were large enough to accommodate internal sodium-salt cooling for both inlets and exhausts. Inlet and exhaust valve head sizes were 35/30.5mm for the 3.2-litre engine and 33/29mm for the 2.1-litre unit. Port diameters were adjusted in proportion. Tappets and hollow camshafts were carried in a magnesium casting, which joined the cylinder heads together along each side. Because magnesium was a poor bearing material, inserts had to be provided for the cam bearings positioned between the cylinders. Chains to drive the cams were discarded and replaced by trains of spur gears, which Porsche had used previously, but only in the 917. The gears were at the front of the block. A gear at the crank nose drove a subshaft at slightly more than half engine speed. This drove the main oil pumps located in the sump.

From the sub-shaft, a train of three gears at each side extended out to the head, running in plain bearings and engaging the gears driving the camshafts. These and the cams respectively had drillings at intervals allowing fine vernier adjustment of valve timing. A single magnesium cover enclosing the camshafts on each side was attached by studs along its periphery. At the front of each exhaust camshaft, a small scavenge pump extracted used oil from its cylinder head and returned it to the reservoir.

A single spark plug was at the centre of the combustion chamber — an advantage of the four-valve head. The back of the right-hand inlet camshaft drove the trigger for the capacitive-discharge ignition system, while the rear of the inlet camshaft on the left side turned the system’s spark distributor. Concentric with the cooling fan, an alternator mounted above the front of the engine was driven by a vee-belt from the nose of the crankshaft. In some installations, a small camshaft-driven vee-belt drove a dedicated pump to circulate the coolant of a water/air intercooler.

Fitted with two compression rings and one oil ring, the piston was full-skirted. Its crown was recessed to give a 7.0:1 compression ratio, an increase from the 6.5:1 ratio customary with the air-cooled head. Fuel supply was still by an electronically controlled mechanical plunger-type injector, which fed the vertical stacks into each cylinder from a plenum chamber.

Kühnle, Kopp and Kausch (KKK) supplied the twin turbochargers. While the smaller 911/78 racing engine could make do with one, the larger Type 935/79 flat-six featured two boost-controlling wastegates. Flap valves in the manifolds released the pressure air when the driver backed off the throttle, a now-well-established Porsche technique to maintain turbocharger speed and improve throttle response. When boosted at 22psi in its 3.2-litre guise, this new twenty-four-valve racing engine produced a quoted 750bhp at 8,200rpm. Team insiders mentioned as much as 840bhp at the higher speed of 8,800rpm. The engine was laid out for a maximum 9,000rpm.

Porsche used Mezger’s new engine in two race cars during the 1978 season. The first was Norbert Singer’s interpretation of then new FIA rules to create the ultimate Group 5 Porsche. According to the new regulations, “body structure” constituted only the area between the front and rear bulkheads, which for Singer meant the engine firewall and the cowl. He replaced the structure outside those two walls with light-alloy tube frames, cut off the nose and tail of a 911 body and attached tubular aluminium frames to carry the suspension, as well as the engine. An internal aluminium roll cage completed what was, in effect, a rigid space-frame structure attached to a 911 platform.

To assist front-engined BMWs, one of the 1977/78 season’s rule changes allowed the floor of a Group 5 car to be raised in order to make room for an underbody exhaust system. “This particular rule was introduced to help teams cut the sills of their cars for exhaust routing,” Singer explained. “The wording of this change was, however, somewhat freely written, which is why we cut out the entire sill, everything! This allowed the car to be lowered a further three inches. Effectively, this Porsche started where its door started.”

Singer’s boss, Helmuth Bott, had allowed the 935/78 project to go ahead, but he had concerns about the team’s interpretation of ‘legality’. “We learned we could entertain pre-scrutineering,” Singer related. “We invited two or three of the FIA people over to Weissach for them to see our new car. One of these delegates was racing driver and journalist, Paul Frère. He couldn’t believe what he was seeing.” Frère, then serving as Vice President of the FIA’s technical committee, later recalled the event. “There was a rulebook definition stating the body of a car was the part comprised between the front and rear bulkheads. We had already changed another regulation by saying that the floor of the body could be raised up to the sill of the door. Singer saw a loophole — he could raise the bottom of the car and drop the whole thing between the front and rear. This is what he did. We were powerless to stop him.”

Frère, who passed away shortly after his ninety-first birthday in 2008, was also amazed by the new car’s doors. “To get better streamlining and to get a better flow to the rear wing, Singer covered the original doors with a fairing. He kept the original shape of the original doors beneath the fairing, but I was very annoyed. Again, however, he showed us our own regulations. There was nothing we could do.”

The wording allowed “aerodynamic devices” not extending beyond the bodyline of the car. Viewed from the front, past fenders that were “free” and allowing fairings out over wider tyres, the doors did not protrude beyond the perimeter of the car. In 1977, Singer had added an additional rear window to the 935 in order to enhance airflow, keeping the original roofline intact underneath the modification. While this modus operandi did not earn an enthusiastic response from the FIA, it was, according to its own book, legal. The precedent was set, Frère conceded. Splitting the technicality, the FIA required Porsche to remove half the cover, revealing half the door beneath. For Singer this was acceptable, but not ideal. In the event, it established a bizarre style adopted by all future builders of such cars.

SIZE MATTERS

As well as lower, this 935/78 was also wider than its predecessors. With the shape of the front fenders free, Singer moved the front wheels further out by making longer wishbones increasing the front track from 1,502mm to 1,624mm. Front wheels were sixteeninchers and, like the nineteen-inch wheels at the rear, were equipped with vaned centrifugal extractors sucking warm air out and away from the brakes.

The front anti-roll bar was cockpit-adjustable. In this car, built from scratch for racing, the driver was placed on the right — the better to see the corners on circuits driven clockwise. These tracks predominated, said Singer, “except for Daytona and the Targa Florio.” Larger rear wheels required the use of special rear suspension arms fabricated from aluminium, with their pivot points raised to give an anti-squat effect on acceleration. In combination with the lowered engine and chassis, the higher wheel hubs were catered for by turning the Type 930 transaxle upside down. This positioned the output half-shafts much higher in relation to the engine, ensuring their universal joints didn’t have to sustain such severe angles.

Builders, such as Cologne-based Kremer Racing, quickly copied this trick, which required a new housing to restore the proper ring-gear position, as well as revised lubrication. There was no differential. It was replaced by a solid shaft or ‘spool’ of titanium. Titanium was also used for the half shafts, “made in a sinfully expensive manner,” said Weissach testing and development driver, Jürgen Barth. “Each half shaft cost eight thousand marks.”

Such a fast and relatively heavy (2,260 pounds) race car needed excellent brakes. For this, Porsche undertook extensive test-rig development. It introduced a powerful new one-piece aluminium brake caliper carrying four 43mm pistons. The caliper gripped a floating brake disc developed from a 917 component. It was 330mm in diameter (instead of 300mm) and 35mm thick. Internal cooling vents were curved. Transverse drillings, which had been found to extend pad life, followed their curvature. Raybestos brake pads were chosen on account of them wearing more consistently than the available Ferodo or Textar alternatives.

Innovative under-skin engineering was matched by the 935/78’s outrageous bodywork. It stretched far to the front and rear, looking ‘evil’ enough for auto motor und sport to label the new Porsche ‘Great White’, referencing the shark kingdom. Porsche chose a different aquatic analogy by nicknaming this new race car ‘Moby Dick’ after Herman Melville’s famous whale.

The car’s widened nose extended forward to a big air inlet for two slightly splayed radiators (feeding the water/air intercooler) and, behind them, the aluminium oil radiator. The radiators for the cylinder heads of the twenty-four-valve engine were in the back fenders, which trailed well to the rear to carry twin mountings for a highplaced wing. Deep downward-extending fences at the ends of the wing were as originally designed and built. Plans to try variations in their shape had to give way to lack of development time.

When the 935/78 was tested by Jacky Ickx at Circuit Paul Ricard in March 1978, the aforementioned door covers were still in place, pending final FIA ruling. The compromise reached with the FIA permitted a cowling over the front half of each door. Without the cowlings, the car’s Cd was 0.383. With them in place, drag coefficient fell usefully to 0.358. To the Porsche’s credit, this was as low as the Cd of the long-tail 917s built specifically for the 1971 24 Hours of Le Mans.

First to test the 935/78 at Weissach was Barth, a frequent racer in his own right. The engine’s power quickly earned his respect. “It was the first car I ever drove where I had to hold on to the steering wheel with both hands,” he recalled. “In its best tune, the standard 935, with full boost, could give 650bhp, but with boost turned up full on this car, we had closer to 900bhp than 800bhp. When the power came on you needed to hold on tight. The handling was even better, though. The earlier 935 was a handful, but this car was lower and lighter. Even with its extra length, the 935/78 was perfect. And weight was only in the centre of the car. The length was just the result of aerodynamic appliances.”

Although Porsche built two Type 935/78s, only one saw racing action. Development problems with the twenty-four-valve engine meant pre-season testing at Circuit Paul Ricard was limited, but the car made a successful debut in the six-hour race at Silverstone, in which it scored its one and only victory by a seven-lap margin in the hands of Jacky Ickx and Jochen Mass. Its practice time set a new record for Group 5 cars.

The team dismissed the next available race, held at the Nürburgring a fortnight later, but during practice for the 1978 24 Hours of Le Mans, Rolf Stommelen was timed at 227.5mph on the Mulsanne Straight. In the race, driven by Manfred Schurti and Stommelen, the 935/78 recorded a best timing of 222mph. Despite this achievement, the outlook was mediocre — the car’s immense speed was nullified by the frequent fuel stops dictated by its mandated 31.7-gallon fuel capacity. Even so, it was performing well, holding sixth place at the race’s seventeenth hour before deterioration of performance led to a complete change of the ignition and injection systems.

Sundry other problems caused various visits back to base. An oil leak was soon discovered, leading the team to treat Moby Dick gently for the final third of the race. In spite of spending two hours and forty-six minutes in the pits, the Porsche finished eighth overall. Only in the post-race teardown was it discovered the oil leak was minor and the engine entirely healthy.

The 935/78 led races at Norisring and Vallelunga, but retired in both. In the German event, faulty brakes forced retirement, while in Italy, the minutes before race end, a stone severed the belt driving the injection pump. Equipped with the biggest turbocharged engine the works team could offer, aerodynamically ingenious and glued to the road by ample downforce, this magnificent car was relished by drivers of the day. As Mezger recalled, it had “insanely huge power.” A factory document states how, at a boost of only 19psi, the engine produced 845bhp at 8,200rpm, with peak torque of 578lb-ft developed at 6,600rpm. At 6,000rpm, the engine was already producing 700bhp! These figures were very little short of the record-setting power levels registered by the turbocharged five-litre Can-Am engines manufactured by Porsche for the 917-campaigning Penske Racing team in 1972.

Twenty years after Moby Dick was built, veteran racer, Brian Redman, had the chance to drive the car at Sebring. “The tyres are very old,” he was warned, “and the differential is locked.” Said Redman, “knowing this would make the car understeer, I approached the last turn before the pits at a very moderate speed, but immediately got into one of the biggest understeer conditions I’ve ever experienced. On absolutely full-right lock, the front tyres squealing in distress, I powered on, missing the solid bank by a margin too close for comfort. Handling? What handling? With over 750bhp on tap from the 3.2-litre engine, there is noticeable lag. Then, when boost kicks in, you’d better be sure that the car is more or less in a straight line. Great fun,” he told Road & Track.

The 935/78 is a super-911 still exciting motorsport fans and marque enthusiasts to this day. It inspired the creative efforts of Porsche customer teams and modifiers running 935s, Brumos and Kremer chief among them, but also many other Group 5 competitors. Mezger, Singer and Moby Dick had much to answer for.

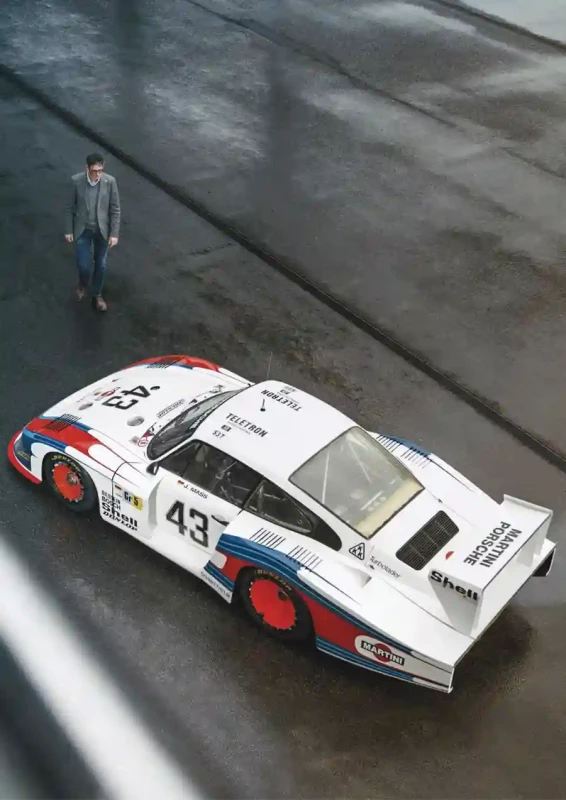

Above The car’s massive power and aerodynamic prowess helped shape the direction many of Porsche’s customer teams would follow with their own 935 racers. Below At the Norisring in 1978 — Moby Dick led the race before retiring due to a faulty braking system Facing page Frank-Steffen Walliser, Vice President of Porsche’s 911 and 718 model lines, pictured with 935/78.

Above In something of a pre-Le Mans shakedown, ‘Moby Dick’ won the 1978 6 Hours of Silverstone Below Despite not winning at Le Mans, 935/78 has gone on to inspire generations of motorsport fans and sired the 991 GT2 RS-based 935 racer.

LARGER REAR WHEELS REQUIRED THE USE OF SPECIAL REAR SUSPENSION ARMS FABRICATED FROM ALUMINIUM

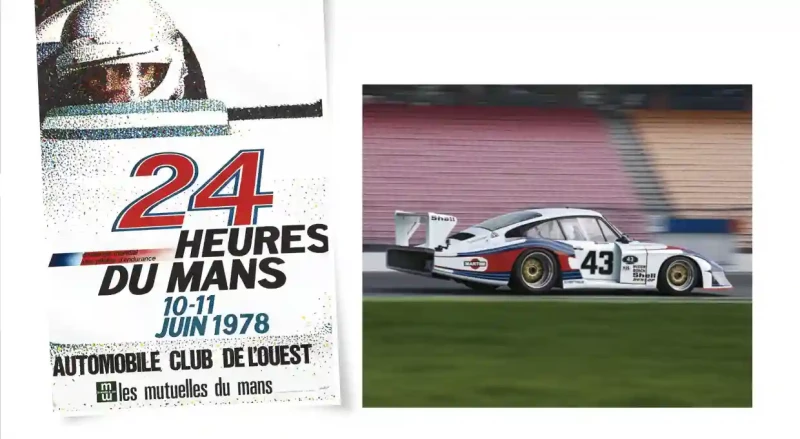

Above Bright red aerodiscs give the car a distinctive look. Above The official programme for 1978’s 24 Hours of Le Mans, which 935/78 was built to campaign.

AN ALTERNATOR MOUNTED ABOVE THE FRONT OF THE ENGINE WAS DRIVEN BY A VEE-BELT FROM THE NOSE OF THE CRANKSHAFT

Below With boost turned up, the factory team were able to realise “closer to 900bhp than 800bhp” during testing