Starting six - design and evolution of the Porsche Type 901 flat-6

Kicking off a three-part series charting the history of air-cooled Porsche engines, we delve into the design and development of the Type 901, which served as the starting point for more than sixty years of flat-six development...

Words Shane O’Donoghue

Photography Dan Sherwood, Porsche Corporate Archives

STARTING SIX

Frankfurt Motor Show, Autumn 1963. The covers were whipped off the 901, a pretty two-door coupe previewing Porsche’s replacement for the highly successful 356. This sensational show car was precursor to the 911 — a name change was required following Peugeot’s challenge to Porsche, when the French car maker claimed rights to three-digit nomenclature with a zero in the middle. The rest, as they say, is storied history, but just as interesting as the svelte new 2+2’s slippery lines was its engine. Carrying on where the design of the 356 left off, the allnew flat-six was mounted behind the rear axle, setting the 911 template, which hasn’t changed dramatically over the course of six decades.

FERDINAND PIËCH WAS RESPONSIBLE FOR MERGING MEZGER’S MOTORSPORT-LED APPROACH WITH PRODUCTION

The story of the then new Porsche engine (retaining 901 designation until 1970) began some time earlier. Ferdinand ‘Ferry’ Porsche was convinced the replacement for the 356 shouldn’t stray too far from the earlier car’s rear-mounted powertrain layout and should continue to make use of an air-cooled boxer. His faith in the effectiveness of this design undoubtedly came from his father, Ferdinand Porsche, an engineering genius responsible for the 356’s parts donor, the Volkswagen Beetle (and much more besides), despite the fact aircooling doesn’t have many clear-cut advantages over liquid-cooling. Sure, you can potentially reduce cost, weight and complexity by ditching the radiator, coolant pump and hoses, but doing so introduces plenty of other challenges, the kind few other car manufacturers persevered with. In contrast, Porsche continued down the air-cooled path, introducing a characteristically large, oversized cooling fan to cope with a wide variety of operating conditions.

It’s worth noting, an engine’s cooling requirements change, not as a function of its speed, but of its power output. It would have been difficult, back in the day, to alter the speed of a Porsche’s cooling fan to meet optimal airflow for the cooling requirements of the engine at any given second. Instead, the flat-six cooling fan is driven by a v-belt from a pulley on the crankshaft, thereby ensuring fan speed is proportional to crank speed. The fan is oversized in order to cover higher ambient temperature conditions. In the case of the Type 901 engine, the fan spins 1.3 times as fast as the crank, though this figure changed throughout Porsche’s aircooled engine development programme.

In short, airflow through the fan is proportional to the crankshaft speed, which isn’t directly related to the cooling needs of the engine. In the interests of safety and reliability, there’s generally more air being passed through the fan than is needed.

The fan draws air in through vents in the bodywork and passes it over the engine. To maximise the surface area for heat transfer between air and engine material, fins are cast into the exterior of the cylinders. Eventually, hot air flows out from the bottom of the engine bay. Heating to the cabin is provided by circulating air around hot exhaust manifolds in simple heat exchangers. The layout of the flat-six, with horizontally opposed sets of cylinders, makes cooling with air much easier than, say, a vee-shaped engine.

The 911’s beating heart is referred to as a boxer due to movement of the opposing pistons being reminiscent of boxers punching fists together at the start of a fight. As opposing pistons reach the bottom and top of their stroke at the same time, they’re in balance, which significantly reduces vibration throughout the engine. Contrary to popular belief, the opposing cylinders aren’t perfectly in line with one another — they’re necessarily offset by distance between the crankpins. This causes a ‘rocking couple’ vibration. Even so, a boxer engine can usually dispense with balance shafts.

Indeed, the flat-six layout eliminates the rocking couple completely and can do without crankshaft counterweights, too. Additionally, a horizontally opposed engine’s centre of gravity can be significantly lower than that of an equivalent vee or inline unit and, of course, the flat engine design allows plenty of room for packaging the rest of the car’s major mechanical components. Nonetheless, the 356’s flat-four had come to the end of its development.

Outright power wasn’t the issue, but the 356’s engine was becoming increasingly expensive to build and service. A new engine was desirable from the point of view of manufacturing costs, enhanced comfort and future development, with an eye on reliability and suitability for motorsport.

Early in the new engine’s design stages, Porsche’s flat-eight Grand Prix unit, under development by legendary factory engineers, Hans Mezger and Hans Honich, was mooted as a possible starting point for Porsche’s new production engine. Reasoning an eight-cylinder lump would result in a much larger car, not to mention a much higher price tag, company big-wigs quickly dismissed the idea in favour of a flat-six. Subsequently, the first proper prototype intended for road use was designated Type 745. Its development was led by Chief Engineer, Klaus von Rücker, and Head of Series Engine Design, Leopold Jänschke, but the resulting engine turned out to be a disaster. It used a cooling fan and two impellers, but its main problem stemmed from the same overhead valve and pushrod arrangement used in the 356, resulting in lots of noise, overly complicated operation and limited performance and revs — the Type 745 began with two litres of displacement, but couldn’t hit the target output of 128bhp (130 metric horsepower), leading to increased capacity of 2.2 litres, even though Porsche wanted to keep engine size down.

It should be known, Porsche’s flat-six design was given dry sump lubrication from the off, mostly to help reduce the overall height of the unit (Ferry Porsche didn’t want the 356’s successor to have a radically different rear profile), but also to reduce drag on the crankshaft and to enable higher cornering speeds without starving the engine of oil. Speaking of the crank, it used just four main bearings, plus a fifth smaller ‘outrigger’. A fascinating insight comes in the form of this translated quote spoken by Mezger, who was primarily working on Porsche’s Formula One project when the Type 745 came to fruition.

“At the time, Porsche was still a very small company. Each department kept a close eye on what the other was doing. Although my team was working on the development of race engines, we knew full well the Type 745 was an engine with push rods, two bottom-mounted camshafts and one crankshaft bearing for every other crank throw. We could see the problem with this idea, even on paper, and we were proved right when the 745 first made it onto a test bench — the engine made a huge amount of mechanical noise and didn’t deliver the necessary performance. In the words of Ferry Porsche after a test drive in the 745-equipped T7 prototype, it simply will not do! Fundamental changes to the engine’s design were urgently required, which is why, when Porsche’s Formula One campaign finally came to an end in late 1962, engineers who had been involved in the project were assigned to the 745’s next stage of development. Two colleagues and I formed a team known as The Engine Group. I was given the task of implementing many of the design changes featured in the second stage of Porsche’s flat-six construction project. The resulting engine was the Type 821.”

Though still a flat-six unit with air cooling, the Type 821 was significantly different from its predecessor. Mezger ditched the valve gear and instead designed a chaindriven overhead camshaft system (one per bank of three cylinders) with one inlet and one exhaust valve per cylinder, allowing higher engine speeds. The cooling system was also redesigned, with a single centrally positioned stationary impeller and, inherited from Porsche’s motorsport programme, a big-end bearing was fitted to the crankshaft for each crank throw. This significantly reduced vibration, while enhancing reliability, even if manufacturing was expensive. An example of the Type 821 engine was, in fact, installed in the 901 demonstrator for exhibition purposes at the aforementioned Frankfurt Motor Show. From Type 821 to realisation of the Type 901/01 was a relatively short hop, although Mezger didn’t do all the heavy lifting. Ferry Porsche’s nephew, the esteemed engineer, Ferdinand Piëch, was responsible for merging Mezger’s motorsport-led approach with the realities of series production. Despite the costs involved, the resulting flat-six made use of much aluminium (the two-piece crankcase, for example) to keep weight down and to enhance cooling. The cylinder barrels were cast iron, however, with the previously referenced finned alloy sleeves cast onto the outside, the design being referred to as Biral and produced by Mahle. These sleeves were separate to one another in order to allow airflow over and around them.

One of the targets set for the 901 engine was to allow for future displacement increases, all the way up to 2.7-litres, which is why the space between cylinders was generous, even considering the relatively wide 80mm bore. This allowed for large valves (39mm for the inlet valves, 35mm for the sodium-filled exhaust valves) to help with breathing. The stroke was only 66mm, meaning the swept capacity of the 901/01 was 1,991cc. The forged aluminium pistons had domed crowns with valve recesses, contributing to the relatively high 9.0:1 compression ratio. Porsche quotes peak outputs of 128bhp and 130lb-ft of torque, but just as interesting, perhaps, was the firm’s confidence in the reliability of its new engine — flat-six-powered Porsches were sold with a one-year, 10,000-mile warranty. In contrast, the 356’s engine afforded owners a six-month warranty. The 901/01’s dry sump lubrication system contributed to Porsche’s sureness. “It’s hard to overestimate the importance of dry-sump lubrication,” Mezger later commented. “Without it, the reliable racing performance of the 911 in later years would have been impossible, given the increasing adhesion of racing tyres and the resulting high lateral acceleration.

The 901 used two oil pumps: one to supply oil to the engine, and the other to take it away again, via the oil filter, to the oil reservoir. Unfortunately, after a year in production, internal camshaft oil passages were found to be insufficient for low engine speed lubrication, hence an oil spray bar being developed thereafter. There was an oil cooler, too, allowing sustained periods of high speed, even in warm climates. Similarly extravagant for a car designed to spend most of its time on the road, at regular speeds, driven by regular drivers, was the carburettor setup. The earliest cars were equipped with a single-choke downdraught Solex unit per cylinder, an electric lift pump from the fuel tank and two mechanical pumps supplying the carburettors. By 1966, Porsche was fitting triple-choke Webers instead.

There are some nineteen different variants of the 901 engine, as far as our research can confirm. Some designs are more interesting than others. The Type 901/02, for example, powered the achingly beautiful 1967 911 S, a car famous for the introduction of the Fuchs five-spoke. The model’s engine was subject to substantial revisions, including reprofiled camshaft lobes, larger valves, larger jets for the carburettors, new exhaust ports and compression ratio raised to 9.8:1. The result was a jump in maximum power to 157bhp, with torque marginally increased. Also, the maximum torque figure of 132lb-ft was produced 1,000rpm higher, at 5,200rpm, hinting at the freer-revving nature of this version of the air-cooled flat-six.

The same year, Porsche launched the 901/03, a detuned version of the engine designed to power the brand’s entry-level 911. Badged with the recently revived T suffix, this 109bhp model was pitched as a replacement for the flat-four-propelled 912 and is recognised for being the least powerful 911 ever assembled. Then, in 1969, to coincide with launch of the longer wheelbase B-series 911, Bosch mechanical fuel injection was introduced to the 911 S and 911 E, the latter a mid-range offering. The S engine received 901/10 designation and its output was upped to 168bhp. In 1970, thanks to a hike in bore size, Porsche’s flatsix received its first increase in capacity, taking the unit to 2.2 litres of displacement. The company took the opportunity to rename the engine (it became the Type 911). Here, abruptly, ends the story of the Type 901 flat-six. Well, sort of. The unit’s influence extends way beyond Porsche engine nomenclature and air-cooling — there’s no getting away from the Type 901 boxer being recognised in all flat-six engine development to the present day. To say this humble two-litre powerplant was important to Porsche would be a gross understatement — we’d go so far as saying it is the foundation of the brand as we know it.

Above The Porsche flat-six has come a long way since its humble beginnings in the back of the 901, evolving to become a powerhouse of performance capable of propelling today’s production 911s to 62mph from rest in an astonishing 2.6 seconds. Above Testing the two-litre Type 901 engine in 1964. Right Type 901 pistons and cylinders photographed in November 1964 Below Installed in the back of a factory fresh 911 in 1965

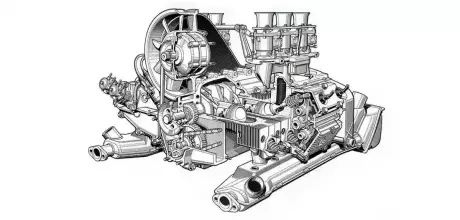

Above A period factory technical cutaway drawing of the Type 901 flat-six Below Type 901 cylinder heads photographed in November 1964.

OUTRIGHT POWER WASN’T THE ISSUE, BUT THE 356’S ENGINE WAS BECOMING INCREASINGLY EXPENSIVE TO BUILD

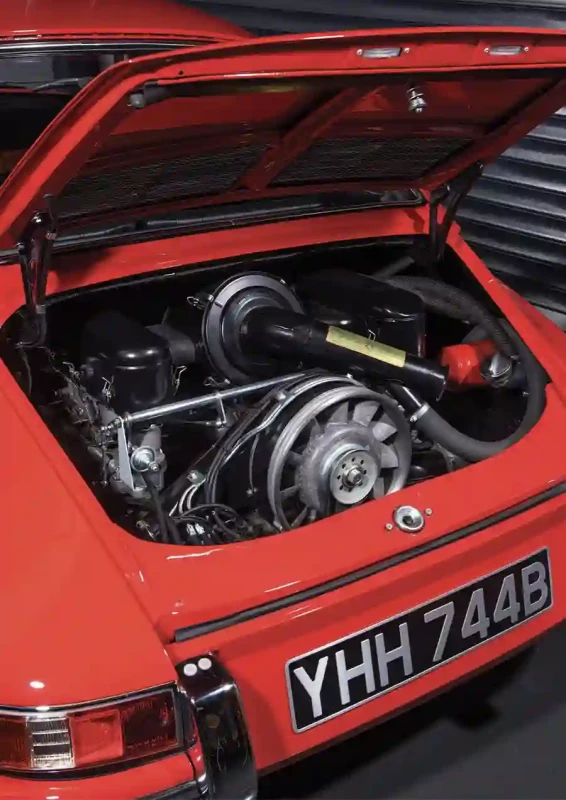

Facing page The first iteration of Porsche’s air-cooled flatsix, seen here in a restored 901, was a watershed moment for Porsche.